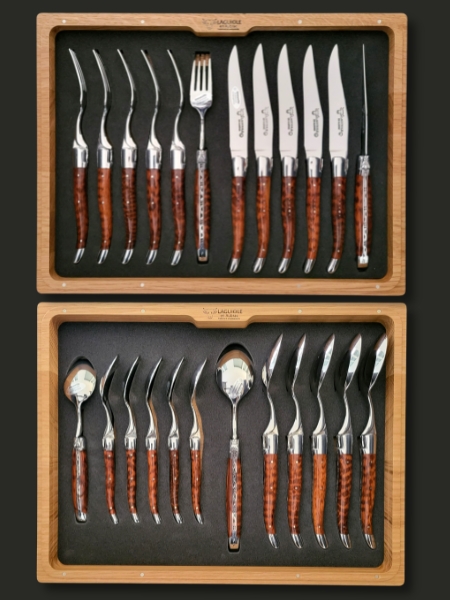

Damascus Blades

Ancestral heritage and unique craftsmanship

The world of cutlery is vast and rich in history. Among the ancient techniques that have spanned centuries and continents, Damascus blades stand out as a true symbol of the art of forging. Combining aesthetics and strength, these blades are the result of unique craftsmanship that continues to fascinate amateurs and professionals alike. In this text, we will explore the origin, characteristics, and manufacturing steps of these exceptional blades.

Damascus blades, also known as pattern-welded steel, are exceptional materials that have marked the history of metallurgy and cutlery. Their fame extends far beyond their region of origin, the city of Damascus in Syria, and their appreciation is now global.

I. Origin of Damascus Blades

Damascus blades take their name from the city of Damascus, Syria, where they were mainly produced during the Middle Ages. However, their history dates back more than 2,000 years, and some historians believe they originate from ancient India. Artisans of that time developed a unique forging technique that gave birth to these distinctive blades, characterized by intricate, wavy patterns and exceptional strength.

II. Characteristics of Damascus Blades

Damascus blades are distinguished by their unique visual appearance, which comes from the overlapping and alternating layers of different metals. This technique, called “pattern welding,” creates varied and unique patterns that make these blades famous. Additionally, the combination of different steels gives these blades increased strength, flexibility, and excellent edge retention.

III. Manufacturing of Damascus Blades

The production of a Damascus blade requires expertise and mastery of ancestral techniques. The process begins with stacking layers of steel with different compositions, which are then heated and hammered. This operation is repeated several times, multiplying the number of layers and creating the distinctive patterns of pattern-welded steel. After this stage, the blade is forged and shaped according to the desired knife type. The blade is then quenched and tempered to ensure its hardness and strength. Finally, the blade’s finish is achieved by careful polishing, which highlights the characteristic patterns of the Damascus steel.

Here are the main steps of this process:

Metal selection: The artisan selects different types of steel, usually a hard steel and a soft steel, to achieve a balanced mix of strength and flexibility.

Stacking and welding: The steels are stacked and welded together, then heated at high temperature to form a solid block.

Forging: The block is forged multiple times, folding and stretching it to create layers of overlapping metal.

Pattern reveal: Once the blade is forged, the artisan quenches and polishes it to reveal the distinctive Damascus patterns.

Damascus blades represent a valuable historical and artisanal heritage, showcasing the talent and craftsmanship of the blacksmiths who create them. Their beauty and quality make them sought-after art and collectible objects. Today, the manufacturing technique of Damascus blades is perpetuated by passionate artisans who continue to keep this centuries-old art alive.