The Montézic Forge

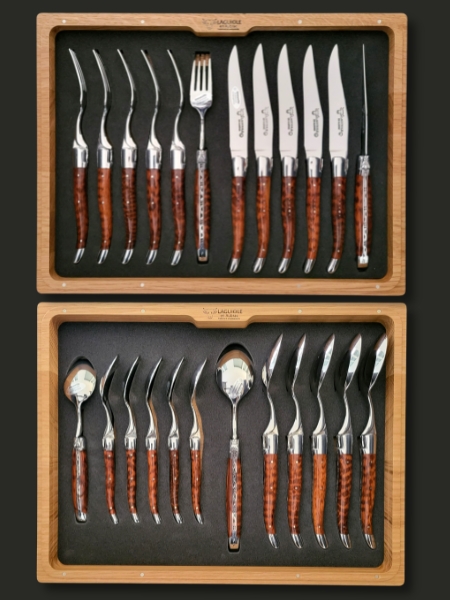

A forge to return to local production

Forging is a crucial step in the world of cutlery. It involves cutting, welding, heating, and shaping the metal to give it its final form. This process requires unique expertise and perfect mastery of these essential tools to ensure the quality and durability of the knives.

The revival of Laguiole knife production in their original region dates back to the 1980s, after a decline that began in the 1920s due to the industrialization of cutlery in the Thiers basin. At that time, eager to preserve the local artisanal tradition, Laguiole en Aubrac established a forge in the charming village of Montézic, not far from Laguiole. Three other cutlery artisans joined this initiative from the very beginning, in the history of the Laguiole en Aubrac manufacture.

Laguiole en Aubrac knife production adheres to strict quality criteria related to local artisanal manufacturing, thus guaranteeing their authenticity. This approach sets them apart from industrial productions and counterfeits.

The forging process generates the knife’s metal components before they are handed over to the cutlers for polishing and various finishes, such as chiseling, guilloché of plates and springs, among others.

To achieve optimal results, an internal quality control is carried out at each stage of the design. This process begins at the Montézic forge, owned by the Laguiole en Aubrac manufacture, where the majority of the metal elements making up our products are created. Some parts may also be subcontracted to Thiers.

CONTINUE YOUR DISCOVERY WITH THESE ADDITIONAL PAGES

Knifemaker’s Workshop

Under the workshop manager’s supervision, Laguiole en Aubrac not only has a woodworking workshop and a forge but also its own assembly workshop. In this workshop, each knife is assembled by the same artisan knifemaker, ensuring constant attention to detail and impeccable quality.