Buying a Laguiole Knife: Guide and Tips

How to choose your Laguiole knife among all the manufacturers?

Choosing the right Laguiole knife can be a complex task due to the number of manufacturers and models available. As a retailer specialized exclusively in Laguiole en Aubrac products, our goal is to guide you and provide you with simple advice to help you make the best choice.

Whether you make your purchase directly from a retailer in-store, through this website, or at one of Laguiole en Aubrac’s physical cutlery shops, we hope you will choose Laguiole en Aubrac, a manufacturer that embodies the excellence of artisanal know-how.

Here are four essential tips to consider when purchasing a Laguiole knife:

Origin and manufacturer’s name:

Make sure your knife comes from a reputable manufacturer known for their expertise. Laguiole en Aubrac is an example of a renowned manufacturer with a long tradition of producing quality knives.

Price, size, and handle material:

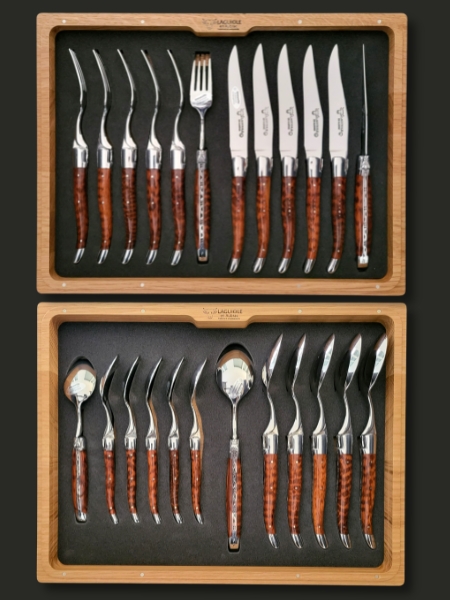

The price of a Laguiole knife varies depending on the size, materials used for the handle, and the complexity of the craftsmanship. Don’t hesitate to compare different models and determine which features are most important to you.

Chiseling work and warranty:

Laguiole en Aubrac knives are known for their meticulous chiseling and careful finishing. Make sure the knife you choose has quality chiseling work and comes with a solid warranty.

The slip joint mechanism:

Traditional Laguiole knives are equipped with a slip joint mechanism, which securely holds the blade in the open position. Make sure the knife you plan to buy has this mechanism to ensure safe and comfortable use.

By following these tips, you will be better equipped to choose the ideal Laguiole knife according to your needs and preferences. Don’t hesitate to consult our selection of Laguiole en Aubrac knives to discover the different options available and find the one that best suits you.

There are several types of locking mechanisms for folding knives, each with its advantages and disadvantages.

Here are some examples of mechanisms commonly used in other types of folding knives:

-

Liner Lock: This locking system uses a thin metal plate (the liner) located inside the handle, which moves laterally to lock the base of the blade in the open position. To close the knife, simply push the liner to the side to release the blade.

-

Frame Lock: Similar to the Liner Lock, the Frame Lock uses the knife frame itself to lock the blade in the open position. The frame moves slightly to lodge under the base of the blade. To close the knife, push the frame to release the blade.

-

Lockback (or back lock): This mechanism uses a spring and lock located in the back of the knife handle. When the blade is opened, the lock engages to lock the blade. To close the knife, press the lock to disengage it and allow the blade to fold back.

-

Slip Joint: This system does not actually lock the blade but exerts tension on it to keep it in the open position. The spring resistance holds the blade in place during use but does not fully lock the blade like other mechanisms. To close the knife, simply apply enough force to overcome the spring resistance and fold the blade back.

-

Axis Lock: This mechanism uses a spring and axis that go through the knife handle and lock onto the base of the blade in the open position. To close the knife, pull the axis back to release the blade.

-

Compression Lock: This system is similar to the Liner Lock but is located on the back of the handle. A metal piece compresses between the base of the blade and the handle to lock the blade in the open position. To close the knife, press the metal piece to release the blade.

-

Ring Lock (or locking collar): The ring lock is a metal ring that surrounds the pivot of the blade and can rotate around it. When the blade is deployed, the ring pivots to lock against the heel of the blade, preventing the blade from accidentally closing during use. To close the knife, rotate the ring to disengage the blade and allow it to fold back. The ring lock is a simple and effective locking mechanism, particularly appreciated for its traditional appearance and ease of use. This type of mechanism is commonly used in classic and regional pocket knives, such as the Opinel, a famous French knife equipped with a safety ring lock.

These locking mechanisms are designed to enhance the safety and functionality of folding knives. The choice of the mechanism depends on personal preferences, intended use, and the characteristics of each knife.

CONTINUE YOUR DISCOVERY WITH THESE ADDITIONAL PAGES

Knifemaker’s Workshop

Under the workshop manager’s supervision, Laguiole en Aubrac not only has a woodworking workshop and a forge but also its own assembly workshop. In this workshop, each knife is assembled by the same artisan knifemaker, ensuring constant attention to detail and impeccable quality.