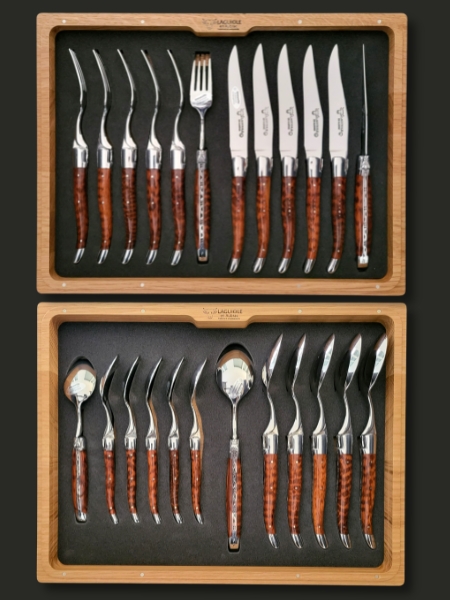

The manufacturing steps of a Laguiole knife, from the blade to the handle

1 - Anatomy of a Laguiole knife 2 - Manufacturing a Laguiole Knife in Video 3 - The manufacturing steps in photosWithin a traditional artisan workshop, a single craftsman is responsible for all assembly stages, from hand guilloche work on the forged spring to the visual adjustment. This way, every piece goes through the hands of the same artisan.

The making of a Laguiole knife requires meticulous work, with nearly 109 operations for a single-piece model (blade only), 166 for the two-piece model (blade and corkscrew), and 216 for the three-piece model (with awl).

It is the journey that the artisan cutler takes the raw materials through, which makes all the difference between industrial production and handmade manufacturing. The latter ensures that each Laguiole is a unique masterpiece.

The origins of Laguiole knives

Laguiole knives were initially handmade in the village of Laguiole, located in Aubrac, France. Cutlers used traditional methods to create these knives, employing local materials such as wood, carbon steel, ivory, and horn.

The blades were hand-forged in local forges, heated at high temperatures, and hammered until they reached the desired shape and thickness. Handles were also hand-carved and shaped, according to customer or artisan preferences.

The knives were then assembled, sharpened, and refined by hand before being polished and engraved as per the customer’s wishes. This handmade craftsmanship ensured high manufacturing quality and meticulous attention to detail, characteristics that still define Laguiole knives today, perpetuated in the village of Espalion by the renowned Laguiole en Aubrac workshop.

1 – Anatomy of a Laguiole knife

The 7 essential parts that make the Laguiole knife indispensable!

Looking for a quality knife for cooking, eating, hunting, or even survival? Look no further! Since time immemorial, the knife has been an everyday object used by humans. And the Laguiole en Aubrac knife is one of the most sought-after for its quality and durability.

But did you know that the Laguiole is much more than just a handle and a blade? In reality, it is made up of multiple components, all essential to its use and performance.

Discover without further delay the 7 essential parts of the anatomy of the Laguiole en Aubrac knife and learn why this item has become a must-have for quality knife enthusiasts!

Part 1: The blade, the soul of a Laguiole knife

The blade is the essential element of a Laguiole knife, allowing for precise slicing and cutting. On this site, only stainless steel blades are offered, ensuring optimal quality without rust and a long lifespan.

The tip, the fragile part of the blade, should be handled with care.

The edge represents the cutting edge of the blade and must be maintained regularly for optimal cutting results.

The bevel is the part that narrows to create the cutting edge, and it must be crafted with precision for optimal cutting efficiency.

Lastly, the back of the blade, opposite the edge, can be decorated, adding a personal touch to the knife.

The blade, the true soul of the Laguiole knife, is a crucial element to consider when choosing a quality knife.

Part 2: The knife handle

The handle is one of the most important parts of a knife, as it allows for a secure and comfortable grip. The choice of handle material often depends on personal preferences, but also on its intended use.

In addition to protecting the hands when using the knife, the handle can also serve as a support for the blade when the knife is folded in the case of folding knives. The bolsters, located at the base of the blade, protect the handle and add an aesthetic touch to the knife. The rivets hold the handle scales in place and ensure the overall strength.

The choice of handle material can also have an influence on the balance of the knife depending on your habits and preferences.

It is therefore important to choose a handle that meets your needs and offers a comfortable and enjoyable grip.

Part 3: Stainless steel or brass bolsters

Often overlooked, the bolster is an essential element of the knife. Located between the blade and the handle, it is found at both ends of the handle and is often made of stainless steel or brass.

There are different models of Laguiole knives depending on the number of bolsters. The crocus model, for example in horn tip, ebony or olive wood, has only one bolster, while other models have two bolsters or more. Knives without bolsters are called “full handle” (bone or buffalo horn).

But what exactly is the purpose of the bolster? The upper bolster, in particular, has a very important function: it serves to support the pivot point of the blade. Thanks to it, the blade can swivel to be safely opened or closed. Additionally, the bolster acts as a protective shield for the knife in case of a fall or impact.

Did you know? Bolsters originally served as repair pieces for Laguiole knives, which in their early days were full-handle, but would break in these areas when dropped.

Part 4: Stainless Steel or Brass Liners

Key elements in the design and manufacture of Laguiole knives, the liners are located inside the handle, between the spring and the handle scales. They provide additional strength to the knife by holding the various parts together, while ensuring great durability. Liners are typically made of brass or stainless steel, but some Laguiole knife models may also feature double liners for even greater strength.

Not only useful for reinforcing the handle, liners can also play an important aesthetic role by being decorated with guilloché, a decorative technique that creates complex geometric patterns using a toothed wheel. This decoration technique is highly appreciated by Laguiole knife collectors, as it adds an extra touch of refinement to the knife and makes it truly unique.

In short, liners are an essential component of Laguiole knives, combining both strength and elegance.

Part 5: The Spring and the Fly/Bee

The central spring is an essential part of the folding Laguiole knife, as it ensures the blade stays in the open or closed position and provides tension for smooth opening and closing. It is located inside the knife’s handle and is usually made of stainless steel to prevent oxidation.

The central spring can also be adorned with guilloché along its length, an engraving technique that adds an extra aesthetic touch to the knife.

The fly (technical term) is located at the end of the spring and is often crafted in the shape of a bee but can also have other motifs such as a clover or a fleur-de-lis. The majority of bees are said to be forged on the spring, as they form a single piece with it. Some can be mechanically welded.

Some Laguiole knife models feature extremely elaborate decorations on both the central spring, like geometric patterns, and the bee, adding a unique touch to each knife.

In summary, the central spring is an important part of the folding Laguiole knife, contributing not only to its function but also to its aesthetics.

Part 6: Rivets

Rivets are metal pieces used in the manufacture of Laguiole knives to hold the various parts of the knife together, particularly the handle and liners. They are typically made of brass or stainless steel and can be visible or hidden during polishing.

Rivets play a key role in the strength and stability of the knife. They help to securely and durably hold the various parts together, which is essential for the safety and longevity of the knife.

Part 7: Handle Scales

Handle scales is the technical term used to define the outer parts of the handle. They can be made of wood, horn, bone, etc. The handle scales are fixed onto the liners.

The manufacturing of a Laguiole knife involves many steps before it reaches your hands! First, the cutler shapes the knife by passing it under abrasive belts. This step refines and outlines the desired shape. Next, the knife passes under a polishing wheel embedded with polishing paste, giving it a smooth appearance. This is how the Laguiole knife is meticulously shaped and finished for a high-quality result.

Manufacturing: Laguiole en Aubrac in Video

2 – Making a Laguiole Knife

Are you interested in the making of Laguiole en Aubrac knives, but would like to know more about the creation process and techniques used? Why not take a look at our videos?

They will allow you to see with your own eyes the precise gestures and care taken at each stage of production. Watching these videos, you will also discover how artisan knife makers transform raw materials into high-quality Laguiole knives.

Settle in comfortably and let us guide you through the creation process of these iconic knives!

3 – Dive into the Heart of Laguiole Knife Making

Key Steps in the Manufacturing of Laguiole Knives

Laguiole en Aubrac knives are a symbol of French craftsmanship and ancestral know-how.

This photo gallery invites you to explore the fascinating world of Laguiole knife making, reflecting a unique expertise and centuries-old tradition. We hope this immersion into the workshops of artisan knife makers will give you a better understanding of the value and exceptional quality of these knives, true objects of art and passion.

CONTINUE YOUR DISCOVERY WITH THESE ADDITIONAL PAGES

Knifemaker’s Workshop

Under the workshop manager’s supervision, Laguiole en Aubrac not only has a woodworking workshop and a forge but also its own assembly workshop. In this workshop, each knife is assembled by the same artisan knifemaker, ensuring constant attention to detail and impeccable quality.