In the 1920s, as many kniveswere produced in Espalion as in the village of Laguiole. Eugène Salettes Street, named after a cutler from the town, is living proof of this. It is the chosen setting for Laguiole en Aubrac to establish itself. The company was born in 1992, in Espalion, from the will of Christian Valat.

The company originally intended to sell Laguiole knives. But Laguiole, like Thiers, had trouble supplying and did not need a commercial company.

With the help of two engineers and Thierry Valat, Christian’s brother, trained at the Pierre Boule marquetry school, they started in a tiny workshop. However, from the outset, they were determined to turn to exporting to promote Aveyron know-how.

In 1993, in association with three other Laguiole artisans, the Montézic forge was created. “In 1996, we bought everyone’s shares because we were doing the bulk of the activity.”

Quickly, the company stands out for the acuity of its commercial approach, openly focused on high-end products. To ensure its development, it creates its own stores, whose location is chosen with particular attention and, in the end, logical based on potential customers.

The success is immediate. So much so that a second store opened in 1995. Then, in 1999, Saint-Émilion and Paris followed as many foreigners pass through there. These are strategic places to make Laguiole knives known.

In 2003, a new store opened on Neuve Street in Rodez. “A bit out of nostalgia for a cutlery shop that dated back to 1930. An ideal showroom for tourist customers from all backgrounds discovering Aveyron. Customers that the company will tirelessly interest with its know-how, as nearly 70% of sales come from Europe.

The result of an active presence in numerous trade shows, such as Frankfurt or Nuremberg. New York gives international scope to foreign customers fond of French-made craftsmanship. Because the image conveyed by Laguiole en Aubrac is an artisanal image of creation and production in continuity with old Laguiole knife models.

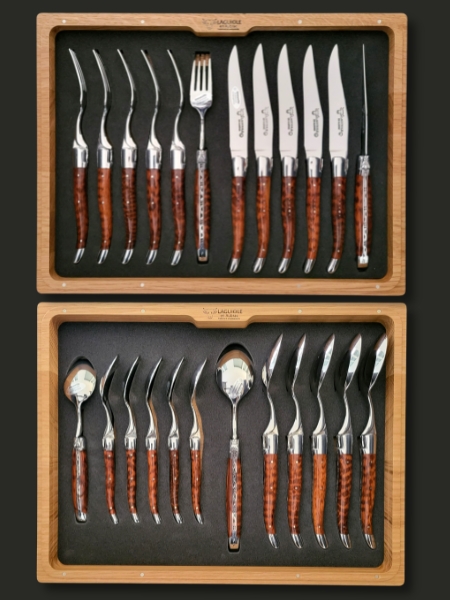

The knife, wide, fits well in the hand. “Proof that we don’t skimp on raw materials (wood, horn…). Because it’s true, we choose to put more material. Some competitors now make “curved” collections. It’s a surprising choice. You either have to put material or not. Or make real curves with protrusions like “plump” ones. Otherwise, nothing.”

It remains to know which materials: “We source some woods from the forest of bees, in Gabon. These are the softest, most beautiful woods in the world.”

Excerpt from the article: source